Why Air Dust Filter Elements Are Crucial for Equipment Longevity

May 23,2025

Why Air Dust Filter Elements Are Crucial for Equipment Longevity

Table of Contents

- 1. Introduction: Understanding Air Dust Filter Elements

- 2. The Importance of Air Dust Filter Elements in Industrial Settings

- 3. How Air Dust Filter Elements Work

- 4. Benefits of Using High-Quality Air Dust Filter Elements

- 5. Importance of Regular Maintenance for Air Dust Filters

- 6. Types of Air Dust Filter Elements

- 7. The Impact of Air Quality on Equipment Performance

- 8. Cost-Effectiveness of Investing in Air Dust Filter Elements

- 9. Conclusion: Ensuring Longevity Through Quality Filtration

- 10. FAQs

1. Introduction: Understanding Air Dust Filter Elements

Air dust filter elements play a pivotal role in maintaining the operational efficiency of industrial equipment. They are designed to capture airborne particles, preventing them from contaminating machinery and compromising performance. As industries continue to grow and evolve, the significance of high-quality air filtration has become more pronounced. This article explores why investing in air dust filter elements is not just a necessity but a crucial step towards ensuring the longevity and efficiency of your equipment.

2. The Importance of Air Dust Filter Elements in Industrial Settings

In any industrial setting, air quality directly influences equipment performance. Contaminants such as dust, pollen, and industrial debris can lead to various issues, including increased wear and tear on machinery. Air dust filter elements act as the first line of defense against such contaminants.

**Key Points:**

- Protects machinery from abrasive particles that cause mechanical failure.

- Reduces downtime and maintenance costs associated with equipment repairs.

- Enhances overall air quality within the work environment, promoting employee health and productivity.

3. How Air Dust Filter Elements Work

Air dust filter elements operate on a simple yet effective principle: they trap harmful particles while allowing clean air to pass through. The filtration process involves several stages:

3.1 Pre-filtration

This initial stage removes larger particles from the air, preventing them from reaching the main filter element.

3.2 Main Filtration

The primary filter element catches smaller particles, including dust and allergens. This stage is critical for ensuring that only clean air enters the machinery.

3.3 Post-filtration

In some systems, an additional layer of filtration may further purify the air, providing an extra level of protection for sensitive equipment.

4. Benefits of Using High-Quality Air Dust Filter Elements

Investing in high-quality air dust filter elements offers numerous benefits that contribute to the longevity of your equipment:

4.1 Enhanced Equipment Efficiency

Clean air is essential for optimal machinery performance. High-quality filters allow for better airflow, which translates to improved efficiency.

4.2 Reduced Maintenance Intervals

Regularly replacing or cleaning air dust filter elements can significantly reduce the frequency of maintenance tasks. This leads to lower operational costs and less downtime.

4.3 Extended Equipment Lifespan

By protecting machinery from harmful contaminants, air dust filter elements can extend the overall lifespan of your equipment. This not only saves money but also ensures that your business runs smoothly over the long term.

5. Importance of Regular Maintenance for Air Dust Filters

Like any component, air dust filters require regular maintenance to function effectively. Neglecting maintenance can lead to clogged filters, resulting in reduced airflow and compromised equipment performance.

5.1 Regular Inspection

We recommend inspecting air dust filters at regular intervals, checking for signs of wear and tear. This proactive approach can prevent costly repairs down the line.

5.2 Cleaning and Replacement

Depending on the environment, filters may require cleaning or replacement every few months. Ensuring that filters are in optimal condition is vital for maintaining equipment efficiency.

6. Types of Air Dust Filter Elements

There are various types of air dust filter elements available, each designed for specific applications:

6.1 HEPA Filters

High-Efficiency Particulate Air (HEPA) filters are designed to trap 99.97% of particles that are 0.3 microns in size. They are ideal for environments that require high levels of air purity.

6.2 Electrostatic Filters

These filters utilize electrostatic charge to attract dust particles, making them highly effective in capturing small particles and improving air quality.

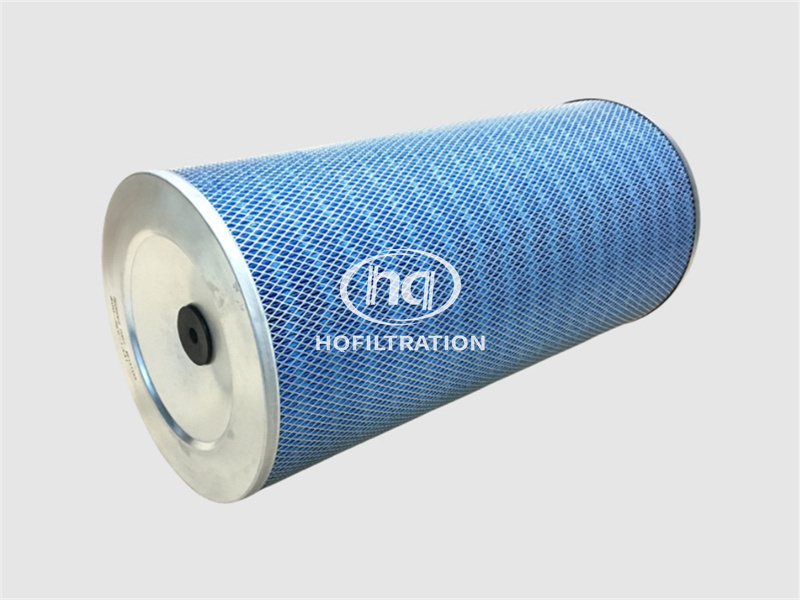

6.3 Cartridge Filters

Cartridge filters are versatile and can be used in various applications. They are easy to replace and maintain, making them a popular choice in many industries.

7. The Impact of Air Quality on Equipment Performance

The quality of air entering industrial equipment can significantly impact its performance. Poor air quality can lead to:

7.1 Increased Wear and Tear

Contaminants can accelerate the wear of machine components, leading to premature failure.

7.2 Decreased Efficiency

Blocked filters can restrict airflow, leading to higher energy consumption and reduced efficiency.

7.3 Safety Hazards

In environments with poor air quality, safety hazards increase, potentially leading to accidents or health issues among employees.

8. Cost-Effectiveness of Investing in Air Dust Filter Elements

While the initial investment in high-quality air dust filter elements may seem substantial, the long-term savings are undeniable.

8.1 Reduced Operational Costs

By preventing machinery breakdowns and minimizing maintenance, businesses can significantly reduce their overall operational costs.

8.2 Improved Productivity

With machinery operating at peak efficiency, employees can work more productively, leading to greater output.

8.3 Long-Term ROI

Investing in quality filtration systems translates into better machinery health and longevity, ultimately providing a higher return on investment over time.

9. Conclusion: Ensuring Longevity Through Quality Filtration

Air dust filter elements are more than just components; they are vital protectors of your machinery. By ensuring that air quality is maintained through high-quality filtration, businesses can significantly enhance equipment longevity, boost efficiency, and reduce operational costs. Regular maintenance, combined with the right type of filter elements, will ensure that your equipment performs at its best for years to come.

10. FAQs

10.1 What are air dust filter elements?

Air dust filter elements are components that capture airborne particles to protect machinery and improve air quality.

10.2 How often should air dust filters be replaced?

The frequency of replacement depends on the working environment, but a general guideline is every 3 to 6 months.

10.3 What types of air dust filters are available?

Common types include HEPA filters, electrostatic filters, and cartridge filters, each suited for different applications.

10.4 How do air dust filters improve equipment efficiency?

By ensuring clean airflow, air dust filters prevent blockages that can lead to energy inefficiency and mechanical strain.

10.5 Can poor air quality affect employee health?

Yes, poor air quality can lead to health issues among employees, including respiratory problems and decreased productivity.

By focusing on these critical aspects of air dust filter elements, we provide a comprehensive understanding of their importance in maintaining equipment longevity and ensuring efficient industrial operations.

TAG:

Contact Us

E-mail :

sales@hqfiltration.com

Phone/Whtasapp:

+8618300643699

Phone/Whtasapp:

+8615239198219

Address:

A15 Aliyun Innovation Center, Wuzhi, Jiaozuo, Henan. China. 454950